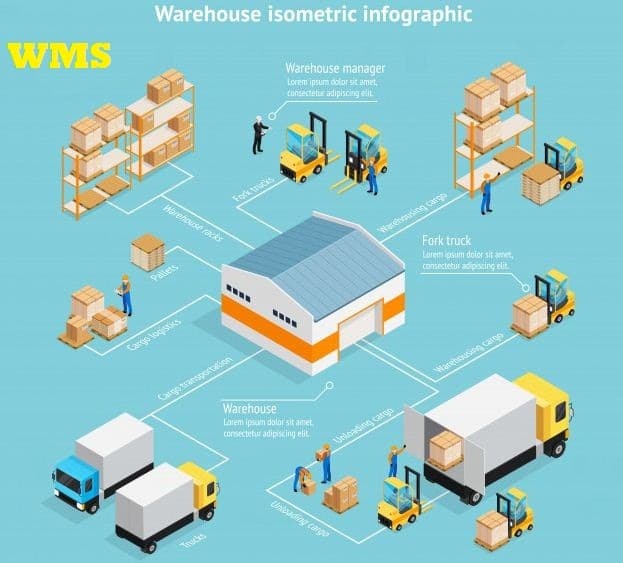

A warehouse management system will be excellent for expanding enterprises with available inventory (WMS). The WMS will improve operational efficiency by monitoring work processes at different levels, raising productivity, and increasing asset utilisation for the workforce and physical space. Inventory control is helped by WMS automation in a way that boosts precision, throughput, and speed. An organisation can gain from a warehouse management system in various ways.

Benefits of Warehouse Management System

Improved Space Utilisation and Lower Operating Costs

Warehouse management systems analyse the optimum use of floor space based on the task and material characteristics to optimise warehouse flow. The usage of space and floor plan analysis is utilised in WMS deployments to decide how space should best be used and gives chances for decreasing waste, including waste of prime floor space and waste of time needed to locate products. A warehouse can save operating costs by choosing the optimal places to keep products as well as supplies or equipment.

Visibility of Inventory

Utilising a warehouse management system will also make correct, current inventory levels visible. This makes it possible for a business to forecast supply more securely and prevent backorders, both of which increase consumer satisfaction. In addition, warehouse management systems collaborate with enterprise resource planning (ERP) and planning activities to supply demand to forecasting activities by exchanging detailed data on how particular items are doing.

Superior Supply Chain

A warehouse management system streamlines the internal operations of a warehouse, which can then affect the wider supply chain. A WMS improves operating efficiencies and lowers costs by streamlining every step of the warehouse process, from inbound receipts to outgoing deliveries. Warehouse staff provide quick and precise shipments by cutting back on or eliminating needless or unproductive activities.

Identifiable Materials

Using lot, batch, and serial numbering, warehouse management systems make it simple to track down inventory goods. Serial numbers uniquely identify an item, while lot/batch numbers identify the batch in which the materials were produced. Full traceability is made possible by using WMS inventory tracking, as was previously mentioned, which enables the ability to link particular lot/batch or serial numbers with incoming receipts and existing shipments.

Efficacious Workforce

A warehouse management system can more effectively assign the appropriate task to the appropriate person at the appropriate time by considering workforces’ skill levels, proximity to one another in the warehouse, their equipment, and the available warehouse tasks. One of the WMS’s significant contributions to better workforce utilisation is optimising journey times within the warehouse.

The benefit of Internal Automation

A warehouse’s utilisation of further automation technologies is made possible by warehouse management systems. Internal work assignments can be automated with the help of mobile devices, which can also help the transition from paper to digital work and activity recording. Processes are made more straightforward, improving scalability and ensuring the information’s accuracy. When mobile devices are paired with the WMS system, the input process can be enlarged due to the availability of access through portable mobile devices.

Enhanced Customer Service

A warehouse system that can modify equipment and inventory movements allows for efficient inbound and outbound planning management. The precise time and date can be planned as inventory is expected, taking into account the workforce and storage equipment on hand. With WMS solutions, receiving dock doors and outbound shipping docks can be planned.

Continuous Development

Warehouse management systems are helpful technology tools that are made to support ongoing development. The system can be implemented in stages to enable regular updates with newly created capabilities, keeping warehouses productive as they adapt to changes in the industry. This permits the warehouse to adopt new procedures and technologies gradually.

GoBOLT provides the best solutions to manage inventory, provide fulfilment options, and handle a wide range of distribution tasks. Every size organisation can benefit from the all-inclusive solution provided by the GoBOLT warehouse management system. It streamlines and optimises warehouses using modules for order administration, purchase tracking, shipping, and other features.

It aids in increasing accessibility and offers a mobile app that includes features for tracking components, managing inventories, selling, buying, and more. In addition, it provides options for both on-premises and cloud deployment. For all business activities, such as inventory control, fulfilment choices, and complete distribution, GoBOLT warehouse management software is essential.

If you’re searching for one of India’s most reliable logistics businesses, you ought to check out GoBOLT immediately.

More Stories

The Impact of Blockchain Services on Enhancing Data Security in Healthcare

How Aluminum Radiators Enhance Engine Cooling Efficiency

Enhancing Grocery Shopping with Colored Thermal Shelf Labels