The assembly of printed circuit boards or PCBs is an interesting phase worth exploring. We know that there is a printed circuit board functioning within every electronic device being sold in the market. The PCB is like the engine that’s responsible for the movement of an entire car. From a thermostat to a DVD, PCB boards are in all electronic devices enabling different functions.

There is no doubt that the creation of functional electronic tools and equipment is not a matter of just putting together a few components. There’s a lot of science and technicalities to this. In this blog post, we will go through the important stages in the PCB assembly process. By the end of this post, you will know what it takes to assemble printed circuit boards into functioning car-like engines.

It’s More than Just Board Being Manufactured

The top thing you need to understand is that the PCB processes can be done only within a specific time duration. And that duration is between the development of an electronic device in its factory. The manufacturing process comes way afterward the assembly of a PCB for a valid reason.

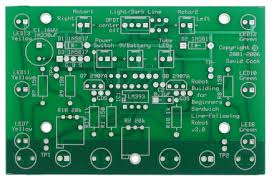

You can consider that the assembly process for PCBs includes bringing everything together on one board. And the purpose of doing so is to get a final product that’s practically functional. Several or even many of the different components are interconnected in such a way that the whole PCB is supposed to perform certain functions. The newly manufactured board is picked and then added with essential components and resistors in order to give life to the function needed to be performed in an eclectic appliance.

The Process of Assembling PCBs

Solder Pasting

The first and foremost is the solder pasting in case you’re intending to do the assembly in a traditional manner. The number one step is to properly apply solder paste. The act of applying solder paste for PCBs is different from THT.

Placing the Various Components

The next phase after pasting the solder is to place essential elements on the board. This is basically a manual job and is done using hands. The other way around is to do a placement with the help of machinery. You simply pick and then place the components.

The THT assembly requires the person involved to place the elements with one hand, but doing that requires special technical expertise. However, the SMT process involves the use of robotics. And the latter method gets the job done fast.

Hole Insertion

The through hole insertion can be done manually if you are following the traditional method of hole insertion. This major phase is done right after the reflow and inspection procedures have taken place.

It is essential to know that soldering is also done manually. When the technician is doing a THT process, the chances of wave soldering are very high. Also, the whole PCB starts to move through coolers in place to make the solder paste solid.

After this, the final inspection takes place in which the PCB is made ready to go.

Read also : EARTHY FURNITURE IS HERE TO STAY

More Stories

How to Install Schutts Industrial Heavy Duty Gas Struts Safely

Custom Portals That Streamline Communication and Knowledge Sharing

How Buying YouTube video likes Can Boost Your Business