In the realm of heavy lifting operations, safety is paramount. Crane load cells play a crucial role in ensuring the utmost safety and efficiency during these critical tasks. These specialized devices are designed to accurately measure the weight and force exerted on cranes, enabling operators to make informed decisions and prevent potential accidents.

Read also Revolver News

As you navigate the intricate world of crane operations, understanding the significance of crane load cell becomes increasingly important. These essential components not only safeguard your equipment and personnel but also contribute to the overall success of your heavy-lifting endeavors.

Importance of enhanced safety in heavy lifting operations

Heavy lifting operations are inherently complex and fraught with potential risks. Even the slightest miscalculation or oversight can lead to catastrophic consequences, including damage to valuable assets, environmental hazards, and, most importantly, the potential loss of human life.

Recognizing the gravity of these risks, it is imperative to adopt comprehensive safety measures that prioritize the well-being of your workforce and the integrity of your operations. By implementing robust safety protocols and leveraging advanced technologies like crane load cells, you can significantly mitigate these risks and foster a culture of safety within your organization.

How crane load cells contribute to enhanced safety

Crane load cells play a pivotal role in enhancing safety during heavy lifting operations. These sophisticated devices accurately measure the weight and force exerted on cranes, providing real-time data that allows operators to make informed decisions and take proactive measures to prevent overloading, structural failures, and potential accidents.

- Overload Prevention: By continuously monitoring the weight of the load being lifted, crane load cells ensure that the crane’s capacity is never exceeded. This safeguards against potential structural failures and reduces the risk of accidents caused by overloading.

- Load Distribution Monitoring: In scenarios where multiple cranes are employed for a single lift, crane load cells provide vital information about the distribution of the load across each crane. This data enables operators to make necessary adjustments, ensuring an even distribution and preventing unbalanced loads that could lead to instability or tipping.

- Real-time Data Analysis: The real-time data provided by crane load cells allows operators to monitor and analyze the forces acting on the crane during the lifting process. This information can be used to identify potential issues or anomalies, enabling timely intervention and preventive measures.

- Compliance with Safety Regulations: Many industries and regulatory bodies mandate the use of load monitoring systems, such as crane load cells, to ensure adherence to safety standards and minimize the risk of accidents during heavy lifting operations.

By incorporating crane load cells into your operations, you not only comply with industry regulations but also demonstrate a commitment to prioritizing the safety of your workforce and the surrounding environment.

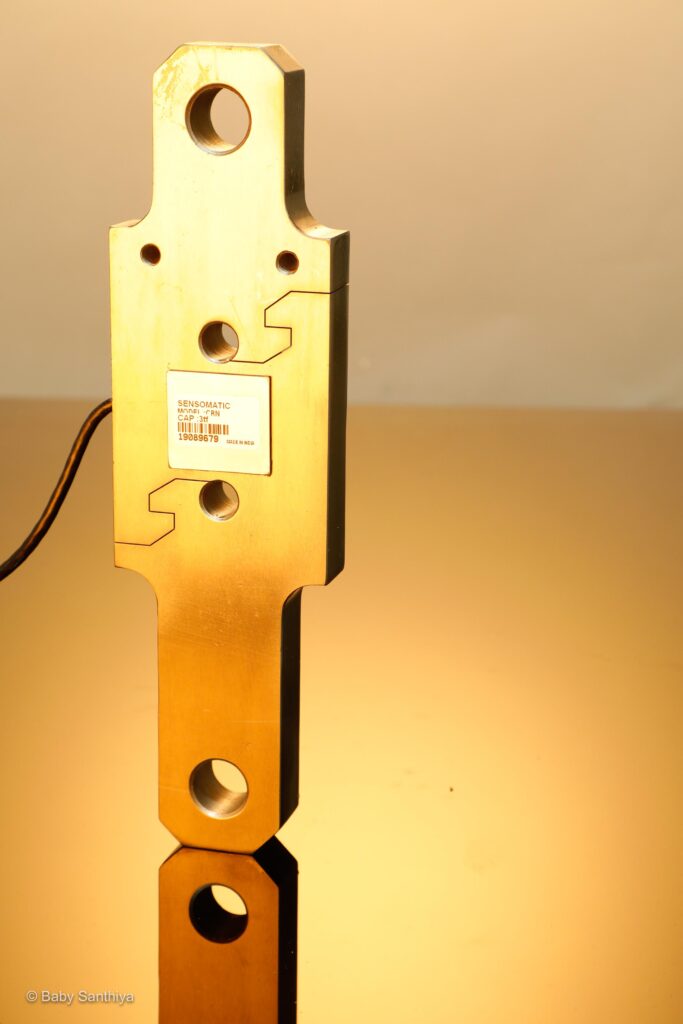

Different types of crane load cells and their applications

Crane load cells come in various types, each designed to meet specific operational requirements and environmental conditions. Understanding the different types and their applications is crucial for selecting the most suitable load cell for your heavy lifting operations.

- Shear Beam Load Cells: These load cells are widely used in crane applications due to their durability and ability to withstand harsh environments. They are designed to measure the shear force exerted on the load cell, making them ideal for overhead cranes and other lifting equipment.

- Compression Load Cells: As the name suggests, compression load cells measure the compressive force applied to them. They are often used in situations where the load is applied vertically, such as in mobile cranes or gantry cranes.

- Tension Load Cells: These load cells are designed to measure tensile forces, making them suitable for applications where the load is suspended or lifted from a single point, such as in tower cranes or winch systems.

- Hydraulic Load Cells: Hydraulic load cells utilize the principles of hydraulic pressure to measure the applied force. They are commonly used in mobile crane applications due to their ability to withstand high shock loads and rugged environments.

- Wireless Load Cells: With the advent of wireless technology, wireless load cells have gained popularity in crane applications. These load cells transmit data wirelessly, eliminating the need for cumbersome cabling and offering greater flexibility in installation and operation.

Each type of crane load cell has its unique advantages and applications, and selecting the appropriate one is crucial for ensuring optimal performance and safety in your heavy lifting operations.

Key features to consider when choosing crane load cells

When selecting crane load cells for your heavy lifting operations, several key features should be considered to ensure optimal performance, reliability, and safety. These features include:

- Accuracy and Precision: Crane load cells must provide accurate and precise weight measurements to ensure safe and efficient operations. Look for load cells with high accuracy ratings and minimal non-linearity and hysteresis errors.

- Environmental Protection: Heavy lifting operations often take place in harsh environments, exposing the load cells to various environmental factors such as moisture, dust, and temperature extremes. Choose load cells with appropriate ingress protection (IP) ratings and temperature compensation capabilities to withstand these conditions.

- Overload Protection: Overload protection is essential to prevent damage to the load cell and ensure its longevity. Look for load cells with built-in overload protection mechanisms or select models with higher safety factors to accommodate occasional overloads.

- Ease of Installation and Integration: Consider load cells that are easy to install and integrate into your existing crane systems. Compatibility with common communication protocols and user-friendly software interfaces can streamline the installation process and reduce downtime.

- Durability and Reliability: Crane load cells must be built to withstand the rigors of heavy lifting operations, including shock loads, vibrations, and continuous use. Choose load cells from reputable Best Load Cell Manufacturers and Suppliers in India with a proven track record of producing durable and reliable products.

- Wireless Connectivity: Wireless load cells offer greater flexibility and convenience by eliminating the need for cabling. If wireless connectivity is a requirement, ensure that the selected load cells comply with relevant wireless standards and provide secure and reliable data transmission.

By carefully considering these key features, you can select crane load cells that meet the specific requirements of your heavy lifting operations, ensuring optimal performance, safety, and reliability.

Pricing factors to consider when purchasing crane load cells

Investing in high-quality crane load cells is crucial for ensuring the safety and efficiency of your heavy lifting operations. However, pricing can be a significant consideration when making this investment. Several factors influence the cost of crane load cells, and understanding these factors can help you make an informed decision.

- Load Capacity: The load capacity of a crane load cell is a primary factor affecting its price. Load cells designed to handle higher capacities generally cost more due to the increased material requirements and manufacturing complexity.

- Accuracy and Precision: Higher accuracy and precision levels in crane load cells typically come at a higher cost. Load cells with tighter tolerances and lower non-linearity and hysteresis errors demand more advanced manufacturing processes and stringent quality control measures, resulting in higher prices.

- Environmental Protection: Crane load cells designed to withstand harsh environmental conditions, such as moisture, dust, and temperature extremes, often carry a premium price tag. The additional protective features and materials used to achieve these ratings contribute to the increased cost.

- Wireless Connectivity: Wireless crane load cells offer greater flexibility and convenience but typically come at a higher price point compared to their wired counterparts. The additional components and technology required for wireless communication add to the overall cost.

- Brand Reputation and Quality: Reputable brands with a proven track record of manufacturing high-quality crane load cells often command higher prices. While these products may initially cost more, they offer long-term reliability, durability, and after-sales support, potentially offsetting the initial investment through reduced maintenance and downtime costs.

- Customization and Additional Features: Customized crane load cell solutions or models with advanced features, such as digital outputs, remote diagnostics, or specialized mounting configurations, may carry a premium price due to the additional engineering and manufacturing requirements.

- Quantity and Bulk Discounts: Many manufacturers offer discounts for larger quantity orders or bulk purchases, which can help reduce the overall cost per unit for crane load cells.

When evaluating pricing, it is essential to consider the total cost of ownership, including installation, maintenance, and potential downtime costs. Investing in high-quality crane load cells from reputable manufacturers can ultimately lead to long-term cost savings by ensuring reliable and safe operations, reducing the risk of accidents and equipment failures.

Advancements in wireless crane load cell technology

In the ever-evolving world of heavy lifting operations, wireless technology has emerged as a game-changer, offering unprecedented flexibility and convenience. Wireless crane load cells are at the forefront of this technological revolution, providing a seamless integration of advanced load monitoring capabilities with the freedom of wireless data transmission.

Traditional wired load cells often present challenges in terms of installation complexity, cable management, and potential signal interference. Wireless crane load cells eliminate these hurdles by transmitting data wirelessly, enabling effortless communication between the load cell and the crane control system.

One of the key advantages of wireless crane load cells is their ability to enhance safety and efficiency in dynamic lifting environments. With real-time data transmission, operators can monitor load conditions and make informed decisions without being tethered to physical cables. This increased mobility and situational awareness contribute to a safer and more efficient work environment.

Advanced wireless crane load cells leverage cutting-edge technologies such as Bluetooth, Wi-Fi, or proprietary wireless protocols to ensure reliable and secure data transmission. These protocols often incorporate robust encryption and error-checking mechanisms, ensuring data integrity and minimizing the risk of interference or unauthorized access.

Additionally, many wireless crane load cells are designed with long-lasting battery life or rechargeable power sources, eliminating the need for cumbersome wiring and reducing maintenance requirements. Some models even incorporate energy-harvesting technologies, such as solar panels or kinetic energy converters, further enhancing their self-sufficiency and sustainability.

As wireless technology continues to evolve, the integration of wireless crane load cells with other smart systems and Internet of Things (IoT) platforms is becoming increasingly prevalent. This integration enables remote monitoring, predictive maintenance, and data analytics, providing valuable insights for optimizing operations and maximizing uptime.

Furthermore, advancements in wireless crane load cell technology have paved the way for innovative applications in areas such as construction, mining, and logistics. For instance, wireless load cells can be seamlessly integrated into mobile cranes, enabling real-time monitoring and load distribution analysis in dynamic lifting scenarios.

While wireless crane load cells offer numerous advantages, it is crucial to consider factors such as wireless range, signal strength, and potential interference sources when implementing these systems. Proper site surveys and adherence to industry standards and regulations are essential to ensure reliable and secure wireless communication.

As the demand for enhanced safety, efficiency, and flexibility in heavy lifting operations continues to grow, the adoption of wireless crane load cell technology is poised to become increasingly widespread, revolutionizing the way we approach load monitoring and crane operations.

Overhead crane load cells and their benefits

Overhead cranes play a vital role in various industries, facilitating the efficient movement and lifting of heavy loads. To ensure the safe and reliable operation of these cranes, the integration of overhead crane load cells is crucial. These specialized load cells are designed to provide accurate weight measurements and load monitoring capabilities, offering numerous benefits to enhance safety and productivity.

- Overload Prevention: One of the primary benefits of overhead crane load cells is their ability to prevent overloading. By continuously monitoring the weight of the load being lifted, these load cells ensure that the crane’s capacity is never exceeded, reducing the risk of structural failures, equipment damage, and potential accidents.

- Load Distribution Monitoring: In scenarios where multiple overhead cranes are employed for a single lift, load cells provide valuable information about the distribution of the load across each crane. This data enables operators to make necessary adjustments, ensuring an even distribution and preventing unbalanced loads that could lead to instability or tipping.

- Improved Efficiency and Productivity: With accurate weight measurements provided by overhead crane load cells, operators can optimize load planning and ensure efficient utilization of the crane’s capacity. This can lead to increased productivity, reduced downtime, and improved overall operational efficiency.

- Compliance with Safety Regulations: Many industries and regulatory bodies mandate the use of load monitoring systems, such as overhead crane load cells, to ensure adherence to safety standards and minimize the risk of accidents during heavy lifting operations.

- Maintenance and Predictive Analysis: By monitoring the load data over time, overhead crane load cells can provide valuable insights for predictive maintenance and identifying potential issues before they escalate. This proactive approach can help extend the lifespan of the crane and its components, reducing maintenance costs and unplanned downtime.

- Integration with Crane Control Systems: Modern overhead crane load cells can seamlessly integrate with crane control systems, providing real-time data and enabling advanced features such as automatic load limiting, remote monitoring, and data logging.

When selecting overhead crane load cells, it is important to consider factors such as load capacity, accuracy, environmental protection, and compatibility with existing crane systems. Additionally, choosing load cells from reputable manufacturers with a proven track record in the industry can ensure reliable performance and adequate support.

By incorporating overhead crane load cells into your operations, you not only enhance safety and productivity but also demonstrate a commitment to adhering to industry standards and prioritizing the well-being of your workforce and assets.

Smart load cells for crane applications

In the era of digitalization and Industry 4.0, the integration of smart technologies has revolutionized various industries, including crane operations. Smart load cells for crane applications are at the forefront of this technological transformation, offering advanced capabilities that go beyond traditional load monitoring.

Smart load cells are equipped with embedded sensors, microprocessors, and communication interfaces, enabling them to collect, process, and transmit data in real-time. These intelligent devices not only measure the weight and force exerted on cranes but also provide valuable insights and analytics to optimize operations and enhance safety.

- Real-time Data Monitoring and Analysis: Smart load cells continuously monitor and analyze the forces acting on the crane during lifting operations. This real-time data can be used to identify potential issues, detect anomalies, and trigger alerts or corrective actions, preventing potential accidents or equipment failures.

- Predictive Maintenance: By analyzing load data patterns over time, smart load cells can identify trends and predict potential maintenance requirements. This predictive maintenance capability can help minimize unplanned downtime, reduce maintenance costs, and extend the lifespan of crane components.

- Remote Monitoring and Control: With integrated communication interfaces, smart load cells can transmit data wirelessly to central monitoring systems or cloud platforms. This enables remote monitoring and control of crane operations, allowing for real-time oversight and decision-making, even in remote or hazardous environments.

- Integration with IoT and Smart Systems: Smart load cells can seamlessly integrate with Internet of Things (IoT) platforms and other smart systems, enabling data sharing and collaboration across various departments or organizations. This integration facilitates data-driven decision-making and optimizes overall operational efficiency.

- Customizable Functionality: Many smart load cells offer customizable functionality through software updates or programmable features. This flexibility allows for tailored solutions that can adapt to changing operational requirements or industry-specific needs.

- Enhanced Data Security: Smart load cells often incorporate advanced security features, such as data encryption and user authentication, to ensure the integrity and confidentiality of sensitive data transmitted during crane operations.

While adopting smart load cells for crane applications may require an initial investment in hardware and software infrastructure, the long-term benefits of improved safety, increased efficiency, and reduced operational costs make them a compelling choice for forward-thinking organizations.

As the demand for digitalization and data-driven decision-making continues to grow, the integration of smart load cells in crane operations will become increasingly prevalent, revolutionizing the way we approach heavy lifting and ensuring enhanced safety and productivity in the industry.

The role of crane scale load cells in weighing heavy loads

Accurate weight measurement is crucial in many heavy lifting operations, whether it’s for load planning, inventory management, or compliance with regulatory requirements. Crane scale load cells play a vital role in providing reliable and precise weight data for these applications.

Crane scale load cells are specialized load cells designed to be integrated into crane systems, enabling the crane to function as a weighing scale. These load cells are typically mounted between the hook and the wire rope or load block, ensuring that the entire weight of the lifted load is accurately measured.

- Inventory Management: In industries such as manufacturing, construction, and logistics, crane scale load cells are invaluable tools for inventory management. By accurately weighing incoming and outgoing materials, companies can maintain precise records, optimize stock levels, and streamline their supply chain operations.

- Load Planning and Distribution: Proper load planning is essential for safe and efficient crane operations. Crane scale load cells provide accurate weight data, enabling operators to calculate the required lifting capacity and distribute loads evenly across multiple cranes or lifting points.

- Compliance with Regulations: Many industries are subject to strict regulations regarding weight measurements and load handling. Crane scale load cells ensure compliance with these regulations by providing accurate and verifiable weight data, reducing the risk of penalties or legal issues.

- Billing and Invoicing: In industries where materials or goods are sold by weight, crane scale load cells play a crucial role in accurate billing and invoicing. By precisely measuring the weight of the loaded or unloaded materials, companies can ensure fair and transparent transactions with their customers.

- Overload Prevention: Integrating crane scale load cells into crane systems can help prevent overloading by continuously monitoring the weight of the lifted load. This feature enhances safety and reduces the risk of accidents or equipment damage caused by excessive weight.

When selecting crane scale load cells, it is essential to consider factors such as load capacity, accuracy, environmental protection, and compatibility with existing crane systems. Additionally, choosing load cells from reputable manufacturers with a proven track record in the industry can ensure reliable performance and adequate support.

By incorporating crane scale load cells into their operations, companies can benefit from accurate weight measurements, improved safety, increased efficiency, and compliance with industry regulations, ultimately enhancing their overall productivity and competitiveness.

Integration of crane load cell systems for improved efficiency

In today’s fast-paced and highly competitive industrial landscape, efficiency is paramount. The integration of crane load cell systems has emerged as a powerful solution for optimizing heavy lifting operations, streamlining processes, and maximizing productivity.

Crane load cell systems are comprehensive solutions that combine advanced load cells with sophisticated software and control systems. This integration enables real-time data acquisition, processing, and analysis, providing valuable insights and enabling intelligent decision-making.

- Centralized Data Management: By integrating crane load cell systems, organizations can consolidate weight and load data from multiple cranes and lifting points into a centralized platform. This centralized data management approach facilitates efficient data sharing, analysis, and reporting, enabling better coordination and collaboration across teams and departments.

- Automated Load Distribution: In scenarios involving multiple cranes or lifting points, integrated crane load cell systems can automatically distribute loads evenly and optimally. This automated load distribution not only enhances safety by preventing overloading but also improves operational efficiency by minimizing the need for manual adjustments and reducing the risk of human error.

- Real-time Monitoring and Alerts: Integrated crane load cell systems provide real-time monitoring capabilities, enabling operators and supervisors to track load conditions, identify potential issues, and receive timely alerts or notifications. This proactive approach allows for swift intervention and preventive measures, minimizing downtime and reducing the risk of accidents or equipment failures.

- Data Analytics and Reporting: By leveraging advanced data analytics tools, integrated crane load cell systems can generate comprehensive reports and visualizations, providing valuable insights into operational performance, productivity metrics, and areas for improvement. These data-driven insights can inform decision-making processes and drive continuous optimization efforts.

- Integration with Enterprise Systems: Many modern crane load cell systems offer seamless integration with enterprise resource planning (ERP) systems, warehouse management systems (WMS), and other business applications. This integration enables efficient data sharing, streamlined workflows, and improved coordination across various departments and processes.

- Scalability and Flexibility: Integrated crane load cell systems are designed to be scalable and flexible, allowing organizations to adapt to changing operational requirements and accommodate future growth or expansion. This flexibility ensures a future-proof solution that can evolve alongside the business.

While the initial implementation of integrated crane load cell systems may require an investment in hardware, software, and training, the long-term benefits in terms of improved efficiency, enhanced safety, and increased productivity often outweigh the upfront costs.

By embracing the integration of crane load cell systems, organizations can unlock new levels of operational excellence, gain a competitive edge, and position themselves for sustained success in the dynamic world of heavy lifting operations.

Conclusion and final thoughts

In the ever-evolving landscape of heavy lifting operations, the role of crane load cells cannot be overstated. These specialized devices have become indispensable tools for ensuring enhanced safety, optimizing operational efficiency, and driving continuous improvement.

Throughout this comprehensive article, we have explored the various aspects of crane load cells, from their fundamental importance in overload prevention and load distribution monitoring to the cutting-edge advancements in wireless technology and smart load cell systems.

As we have seen, the integration of crane load cells not only contributes to a safer work environment but also enables data-driven decision-making, predictive maintenance, and seamless integration with IoT platforms and enterprise systems. By leveraging the power of these advanced technologies, organizations can unlock new levels of productivity, efficiency, and competitiveness.

However, it is crucial to remember that the successful implementation of crane load cell systems relies on a holistic approach. Selecting the right load cells from reputable manufacturers, considering factors such as accuracy, environmental protection, and compatibility, and ensuring proper installation and integration are all essential steps in maximizing the benefits of these systems.

As you embark on your journey towards enhanced safety and operational excellence, consider investing in high-quality crane load cell solutions. By partnering with trusted industry experts and leveraging their knowledge and experience, you can navigate the complexities of heavy-lifting operations with confidence, ensuring the utmost safety for your workforce and assets while driving sustainable growth and success for your organization.

In the ever-evolving world of heavy lifting operations, the role of crane load cells will continue to evolve, offering new possibilities and solutions to the challenges of tomorrow. Embrace this technology, stay ahead of the curve, and position your organization at the forefront of innovation and safety in the industry.

More Stories

Optimizing Route Planning with Courier Software

Site Oficial Para Cassino Online At The Apostas No Brasil

Site Oficial Para Cassino Online At The Apostas No Brasil